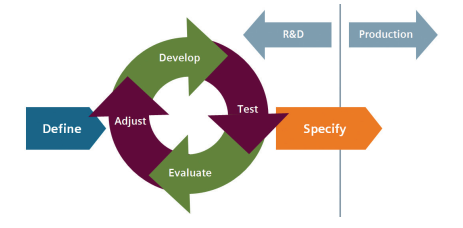

Manufacturing Execution System (MES) is the proposed solution to solve the link gaps between the ERP system and the centralized integrated production automation process management system and site monitoring. real-time manufacturing with the goal of improving productivity.

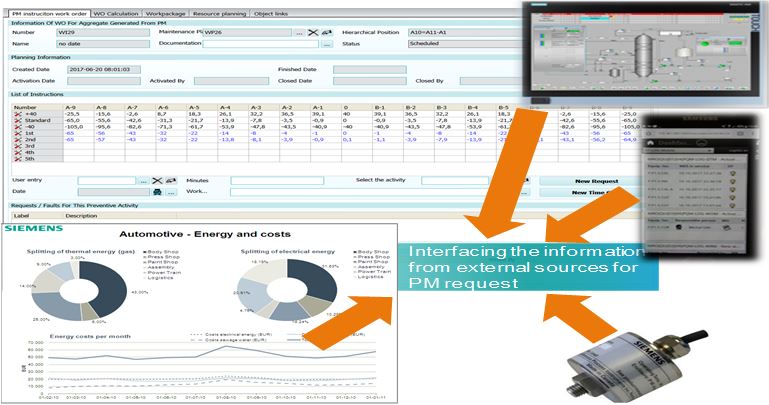

MES is a connected information system with functions such as: tracking, monitoring, storing and continuously updating information from the factory and production area right at the time of operation.

The MES solution deployed on the Siemens platform has been introduced by ESTEC into a number of large-scale manufacturing industries in Vietnam. In the absence of a manual MES, operators are prone to errors and omissions, there is no real-time support for the production system, and there is no suitable production process, which slows down the production schedule, leading to losses. raw material costs, operating costs in production.

.jpg)

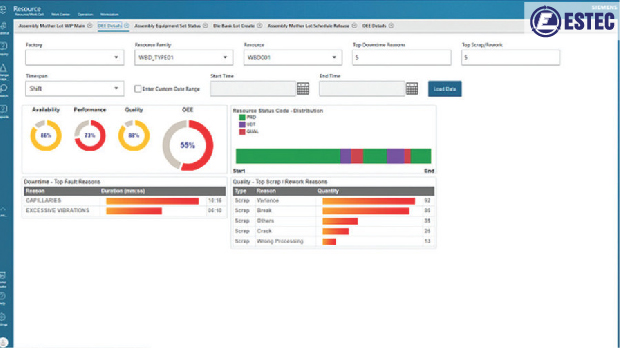

Opcenter Execution Core is a semiconductor-specific manufacturing execution system (MES) with detailed visibility into enterprise operations, real-time access to process production with quality monitoring Real-time monitoring and display, smart and easy interaction.

ESTEC is Siemens' formula partner in Vietnam in digital solutions, including Opcenter Execution Core (MES) manufacturing execution system solution for semiconductor companies.

Opcenter Execution Core (MES) automates production execution and quality control, reduces risk, operating costs, and improves production efficiency, and powerfully works with any system. For example, integration with enterprise resource management (ERP), product life management (PLM), supply chain management (SCM), customer management (CRM).

Opcenter execution core provides the following benefits and features:

Manufacturing execution

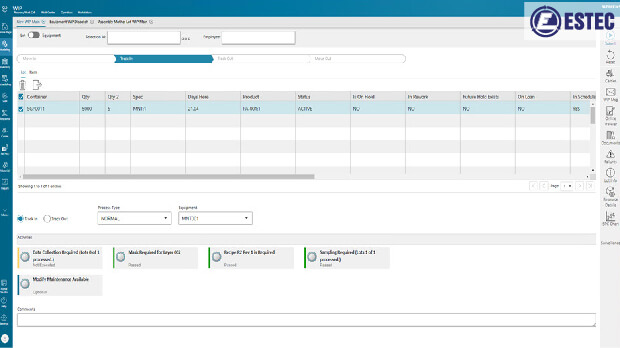

• Paperless manufacturing

• Product/work-in-progress (WIP) trace-ability, genealogy and audit trail

• Process, operator, equipment and materials enforcement

• Data collection and process limits

• Searchable electronic audit trail

• Forward/backward traceability and correlation

• Containment management

• Lean and Six Sigma enablement

• Intuitive user interfaces

• Streamlined validation

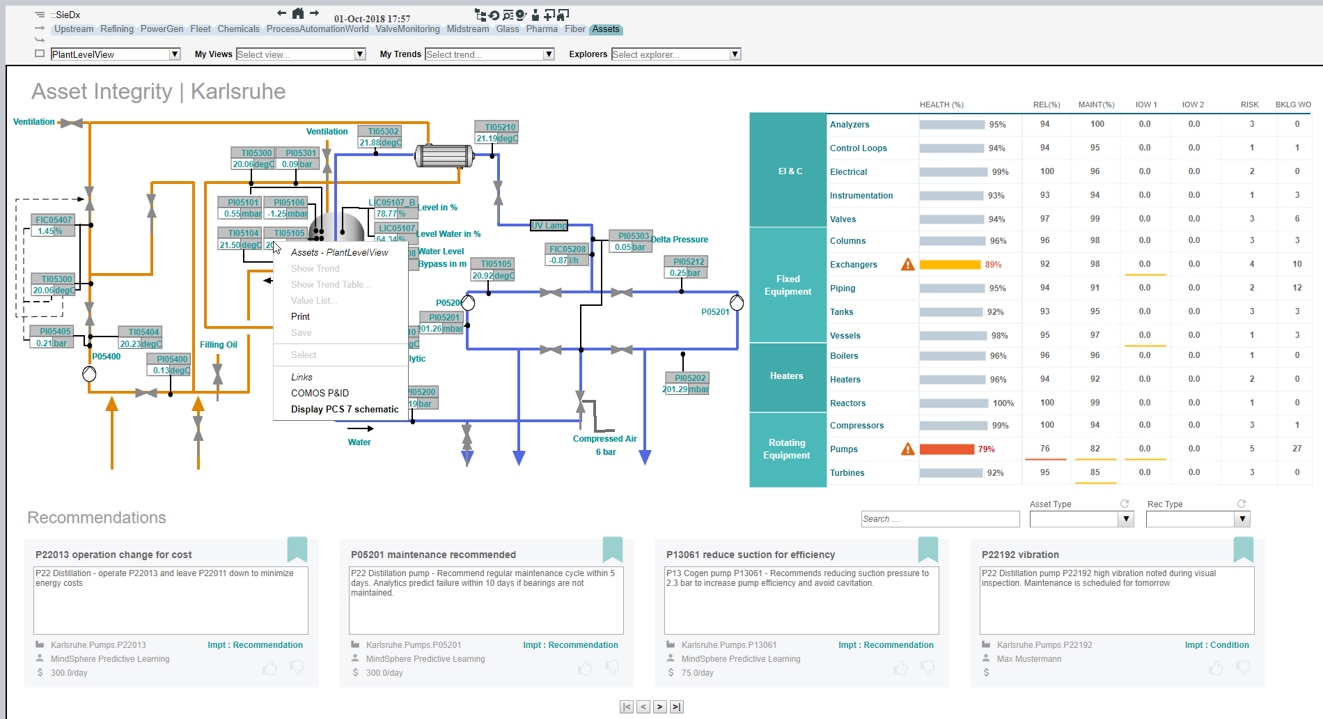

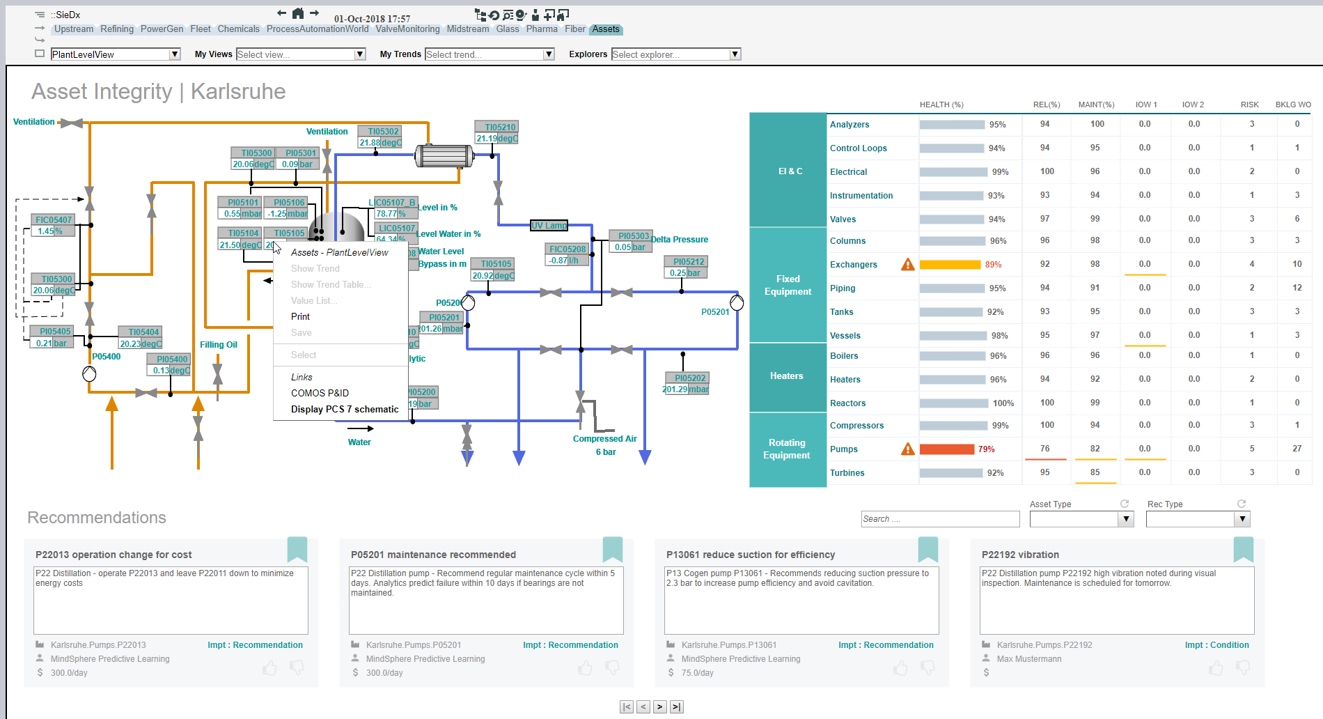

Ultimate control and visibility

• Dispatch management

• Flow management

• Operator training certification

• Electronic signatures

• Electronic procedures

• Equipment maintenance manage-ment and certificatio

Opcenter execution core customers realize:

Proactive control and quality

• Automatic enforcement of best practices

• Continuous feedback to operators

Granular enterprise visibility:

• Instant access to production, process and quality dashboards

• Multisite, comparable performance reports

Continuous improvement

• Reduced variability

• Correlation of manufacturing results for true root cause determination

Brand risk reduction

• Assured product release with self-auditing of as-manufactured records

• Containment of suspect material with complete genealogy and traceability

Improved profit margin

• Higher throughput, capacity, yields and manufacturing velocity

• Reduced cost of good and poor quality

Should you invest in a production execution system?

Investing in MES is a long-term and fundamental “profit”. The MES line factory produces products that are different in quality than the market. Higher production efficiency increases competitive advantage over competitors. Especially in large production lines that need to manage the entire automatic production process, it is always necessary to have a MES system to help improve the competitiveness of enterprises.

With a team of experienced engineers in many industries and well-trained, technology transfer from Siemens experts. ESTEC is confident to be the leading solution provider for Opcenter Execution Core in Vietnam.

Contact us now for more detail:

Hotline : (+84) 28 5446 4649 (ext 202)

Fax: (+84) 28 5446 4648

Email: info@biendongco.vn