In the context of businesses increasingly focusing on cost optimization and sustainable development, effective energy management has become a key factor for maintaining a competitive edge and achieving the government-mandated Net Zero goals by 2050.

1. Overview

SIMATIC Energy Management System - A Comprehensive Platform for Monitoring, Analyzing, and Managing Industrial Energy Use

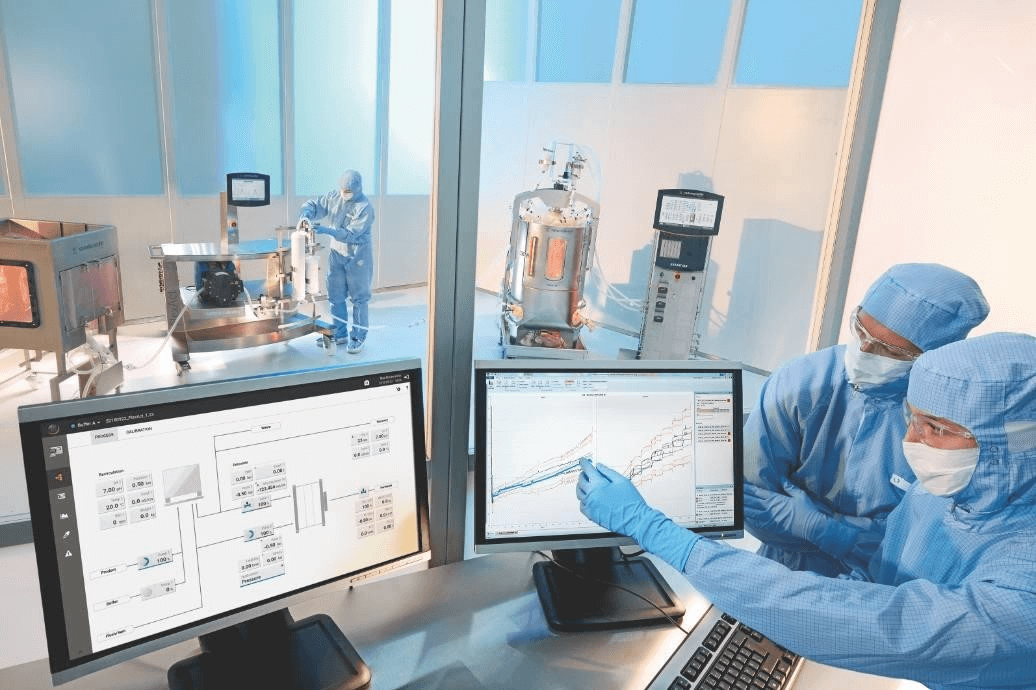

SIMATIC Energy Management, Siemens’ comprehensive energy management solution, is becoming an invaluable tool for businesses to monitor, analyze, and optimize energy usage. With strong integration capabilities and a full suite of features, this solution not only helps reduce costs but also contributes to lowering environmental impact and meeting international standards.

SIMATIC Energy Management offers numerous benefits for businesses across various sectors. Firstly, the solution significantly reduces operating costs by identifying and leveraging energy-saving opportunities. Continuous monitoring and analysis of energy consumption during production lay the groundwork for optimizing production processes, enhancing efficiency, and reducing costs.

.jpg)

In addition, SIMATIC Energy Management plays a crucial role in minimizing environmental impact. The solution includes features for calculating and reporting the amount of CO2 emissions based on energy consumption. This capability enables businesses to strategically optimize energy use, helping to reduce emissions while aligning with the current global trend towards green and sustainable development in pursuit of Net Zero goals.

.jpg)

.jpg)

2. Features of the Energy Management Monitoring Software

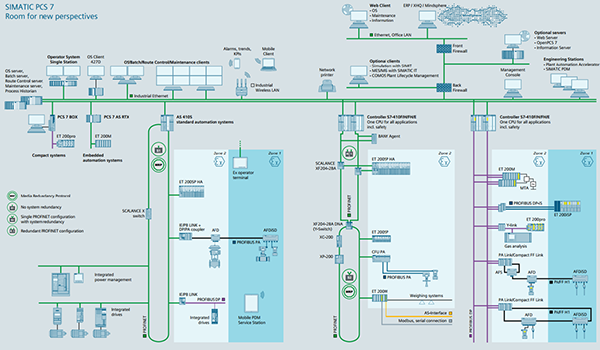

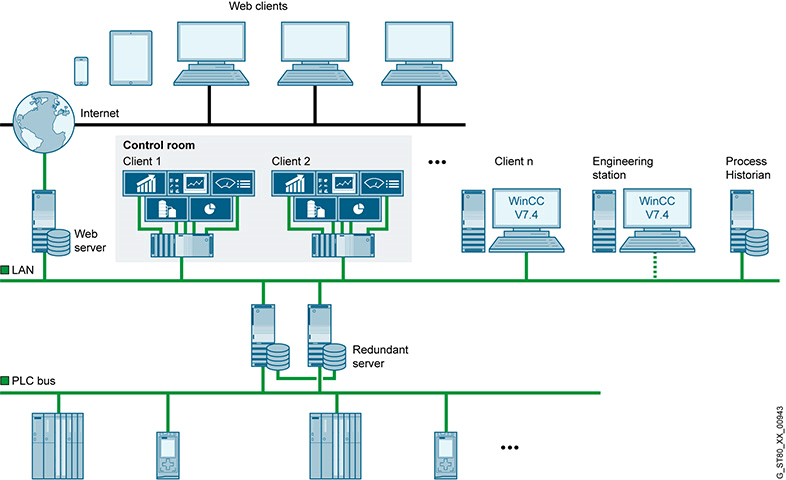

The solution is built and deployed on a cloud platform or on-premises (dedicated server) based on the specific requirements of each business. This allows for centralized monitoring, connecting multiple factories across different geographical locations within the same corporation.

.jpg)

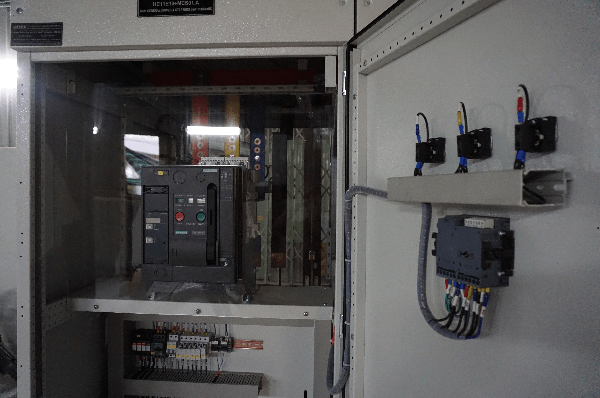

The software is not limited to existing meter types at each factory or business; it can collect data from any energy meters using a variety of communication standards such as Modbus RTU, Modbus TCP, Ethernet, BacNet, etc. This flexibility helps customers save on investment costs when implementing projects.

.jpg)

In addition to monitoring electrical energy, the software also collects, monitors, and statistics other forms of energy such as gas, compressed air, and water.

The software allows for flexible reporting on an hourly, weekly, monthly, or yearly basis, catering to the diverse needs of customers.

.jpg)

One of the core features allows for continuous monitoring of energy consumption at each area, device, or production process. This not only helps identify performance issues but also provides timely adjustment solutions. The feature quickly identifies high energy consumption points, enabling businesses to focus on the most effective energy-saving measures.

.jpg)

Additionally, the system supports cost calculation based on consumption levels. This feature is commonly applied in sectors such as rental apartments and shop houses, where the data is transparently accurate and easy to monitor by both the end users and the energy providers.

.jpg)

3. Practical Applications for Businesses

Energy management monitoring software in general, and SIMATIC Energy Management software in particular, is widely used across various sectors, from manufacturing and processing industries to smart buildings and other infrastructure areas. In manufacturing plants, the system helps optimize energy consumption, minimize waste of electricity and gas, thereby reducing production costs. For processing industries, the software supports energy management in complex processes, enhancing operational efficiency and reducing unnecessary costs.

In the era of Industry 4.0, where cost optimization and sustainable development have become essential trends, effective energy management is one of the key factors for business success. With this solution, companies not only save energy but also increase production efficiency, ensure compliance with international standards, and protect the environment. This is an optimal solution that helps Vietnamese businesses thrive during the digital transformation and aim for sustainable development in the future. ESTEC (Eastern Sea Automation Technology Engineering Co., Ltd.) is an official partner of Siemens in Vietnam, specializing in consulting and building automation and digitalization solutions for various industries. ESTEC is committed to accompanying businesses in achieving their Net Zero goals.

Please contact us for detailed advice on the solutions!

Contact Information:

Hotline: (+84) 28 8886 8799

Email: sales@biendongco.vn