Review part 1 at: http://estec.vn/en/automation-solutions-plc-scada-part-1.html

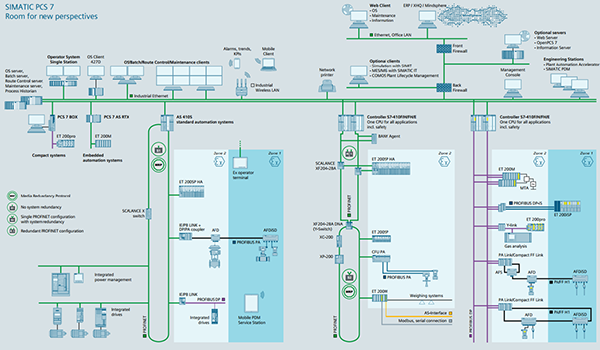

In fact, both solutions were applied to WinCC program by Siemens to monitor, data acquisition and control the automation system of production processes. The extended functions with the most remarkable features of WinCC:

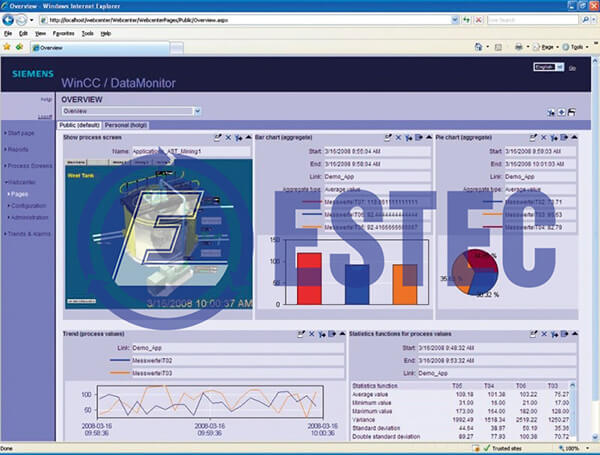

WinCC / DataMonitor: This function is used to displaying, analyzing, evaluating and distributing the current process status, data and information. With the DataMonitor, WinCC data processes can be provided to all functional levels of a company through the Web.

Function WinCC - DataMonitor

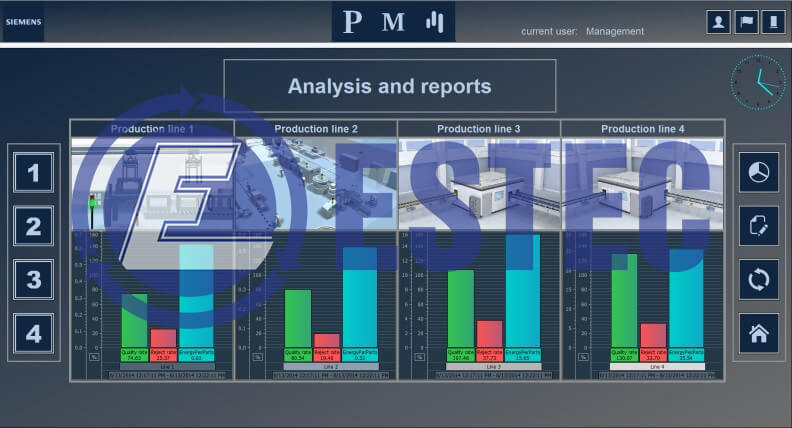

WinCC / PerformanceMonitor: With this function, the main data for individual devices, machinesor the entire production lines of the factory can be calculated and analyzed towards each machine or the whole line.

Function WinCC - PerformanceMonitor

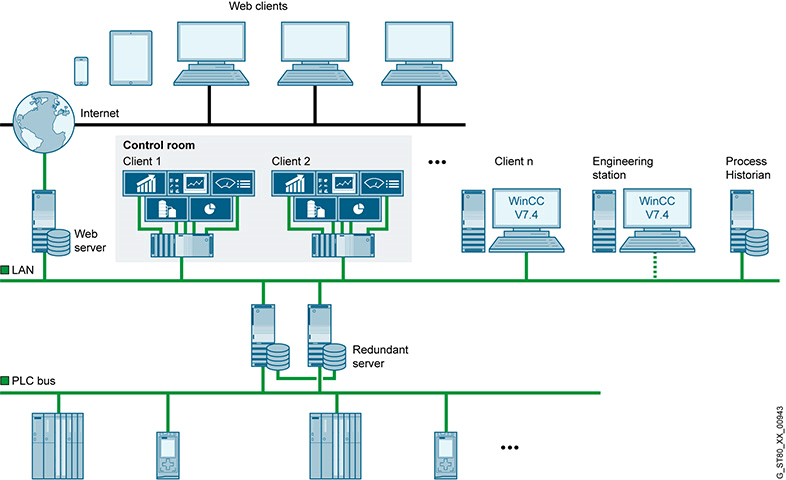

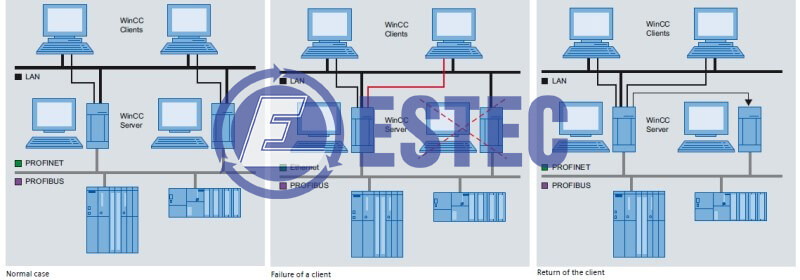

WinCC / Redundancy: Provides customers with the option parallel operation of two WinCC systems or servers are connected together to monitor each other. If one of the servers fails, the second server will control the entire system. After the failed server is operative again, the contents of all messages, process values and data processing during operation as well as the internal tags will be synchronized online.

Function WinCC- Redundancy

WinCC / SES (Sequence Execution System): This function was designed to control the sequence for processes based on formulas and sequences such as mixing processes in the production of food and beverage. Using templates and intuitive function blocks predefined can be achieved high level of technical efficiency. That's why factory engineers can save technical time as well as testing and operation time.

WinCC / Web Navigator: Allows controlling, monitoring and operating the factory through the Internet or Intranet without changing the WinCC program.

Besides the functions mentioned above, the solution PLC - SCADA also provides customers with some other functions such as:

- SIMATIC WinCC / Audit: Monitor and record all data changes in the database.

- WinCC / Calendar Scheduler and WinCC / Event Notifier: A calendar function has been added based on the calendar function of WinCC.

- WinCC / ChangeControl: Support for troubleshooting and reduce downtime of the factory.

- WinCC / Connectivity Pack and Connectivity Station: Control, monitor the system remotely through additional options.

- WinCC / TeleControl: The network topology and protocols supported diversity allows flexible configuration according to individual requirements.

- WinCC / WebUX: Was developed for on all platforms without installation to using WebUX.

Combined with the operation control software indispensable for programmable logic controller. For compact control solutions and integrated functions, powerful controllers for highest demands or controller for a distributed architecture or PC-based automation. Portfolio of Siemens ‘ SIMATIC Controller with PLC suitable for each requirement:

Basic Controllers: SIMATIC S7-1200.

Basic controller is the smart choice for compact automation solutions with communication functions and integrated technology. They are available in both standard and safety version.

Advanced Controllers: SIMATIC S7-1500, SIMATIC S7-300, SIMATIC S7-400.

Advanced controllers automation not only support for complete production of factory but also applications that require performance, flexibility and connectivity highest network. SIMATIC S7-1500 controller generation is the latest and also the most future proof with optimal system performance.

Distributed Controllers: SIMATIC ET 200SP CPUs, SIMATIC ET 200SP Open Controller, SIMATIC ET 200pro CPUs.

Distributed controllers are used for machines with a distributed architecture and machines with limited space. They combine the advantages of SIMATIC S7-1500 with design of SIMATIC ET 200SP. With SIMATIC ET 200pro, a CPU module with S7-1500 technology is available as a space-saving solution for harsh environmental conditions.

Software controllers: SIMATIC S7-1500 Software Controllers, SIMATIC ODK 1500S, SIMATIC WinAC.

Software controllers are used wherever precision and maximum speed as well as automation on PC. PC-based controllers operate independently of the operating system.

Depending on the technical requirements of the system, ESTEC will offer appropriate solutions, optimizations and latest updates of the company on equipment and software.

As one of the leading companies in the market of automation and digitalization, ESTEC have the experienced of successfully implementation of many projects applying solution PLC - SCADA in industries, with process of management design and deploy projects that meet ISO 9001: 2015 standards.

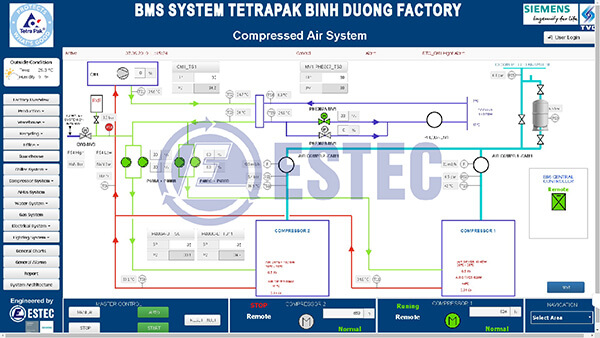

Project: Supplying Control System and Instrumentation for BMS system - TETRA PAK using TIA Portal V14 SP1, PLC S7-1500 and Webfactory’ SCADA software.

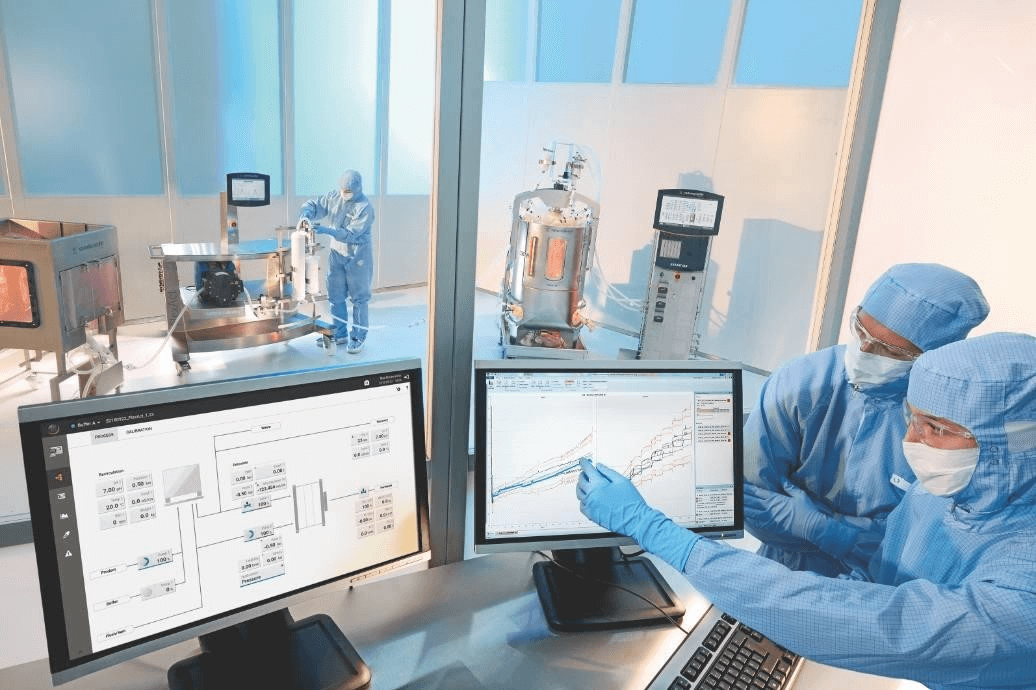

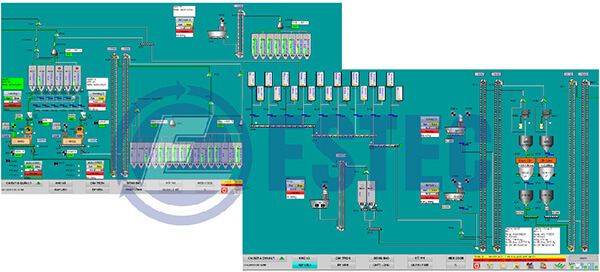

Operation Screen of the Project

Please see details here: http://estec.vn/en/automation-electrical-solutions/supplying-control-system-and-instrumentation-for-bms-tetra-pak.html

Project: Supplying Control Panel, Industrial Network, Software and Installation for Control Production Operation System – GREENFEED using TIA Portal V14 SP1 and SIMATIC S7-1500, ET200SP

Operation Screen of the Project

Please see details here: http://estec.vn/en/automation-electrical-solutions/supplying-equipment-and-control-production-operation-system.html

ESTEC is the solution partner of Siemens in consulting, deploying Automation Solutions PLC – SCADA to meet the technical requirements, the production technology of factories and industries. With team of experience engineers in industries and usally up-to-date technology from Siemens, ESTEC is confident to be a provider of leading solutions for PLC – SCADA, please contact us immediately for detailed consultation.