The solution for monitoring the status of the Flender gearbox

The solution for monitoring the operating status of the Flender gearbox

In order for a production line to ensure stability and continuity, equipment needs to be monitored, checked and maintained at the right time to increase the life of the equipment and ensure it is always ready.

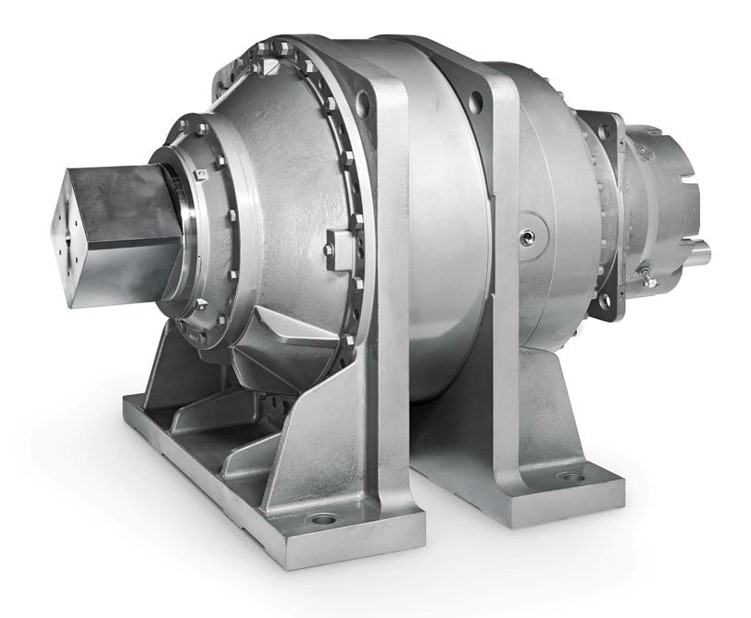

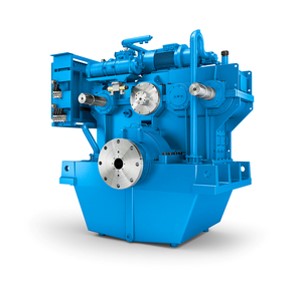

ESTEC is Flender's partner in providing a solution for monitoring the operating status of the Flender gearbox. The solution not only for the factory to monitor the vibration of the bearings, but also to capture the overall operating status of the gearbox from torque, temperature, pressure, vibration ... Meanwhile, the plant will have plans to increase or decrease operating productivity accordingly and effectively.

The solution for monitoring the operating status of the Flender gearbox

In order for a production line to ensure stability and continuity, equipment needs to be monitored, checked and maintained at the right time to increase the lifespan of the equipment and ensure it is always ready.

ESTEC is Flender's partner in providing a solution for monitoring the operating status of the Flender gearbox. The solution not only for the factory to monitor the vibration of the bearings, but also to capture the overall operating status of the gearbox from torque, temperature, pressure, vibration ... Meanwhile, the plant will have plans to increase or decrease operating productivity accordingly and effectively.

Solution's features such as:

- Early detection of wear and tear and abnormality of the gearbox during operation.

- Can monitor the input shaft speed and torque.

- The vibration signals from the bearing, temperature, and the operating pressure of the gearbox are closely monitored.

- Fully integrated solution for monitoring the most complex drive systems.

- If there is any potential error of the gearbox, the expert will send a report with in-depth analysis including information with recommendations for handling.

- Data is always recorded 24/24 and continuously transmitted securely to Siemens - Flender center for monitoring and analysis by experienced experts. The report will be sent regularly by the expert with the following expert analysis and recommendations for upcoming handling.

- In the absence of potential errors detected, reports will be sent to customers every 6 months.

Potential gearbox failures, when detected early, allow more time for the factory to prepare the necessary parts and plan the maintenance thoroughly and best. The Flender gearbox operating status monitoring solution is used in industries such as cement, mining, iron and steel, petrochemical refining, fertilizer, power generation plants, sugar cane factories, etc. Large gearboxes installed for vertical mill, ball mill, separator, bucket conveyor, press, crusher, crane,….

Benefits of the solution to monitor the operating status of the Flender gearbox:

- Reduce maintenance costs, have a better maintenance plan.

- Assist maintenance department in warning of damage caused by operation overload.

- Early detection of anomalous positions, grasp the cause and the direction to be handled.

- All maintenance activities are planned in advance, optimized for spare parts storage.

- Improve productivity and efficiency in operation.

ESTEC not only provides products and solutions with high quality and reliability, but also focuses on after-sales services for customers.

Our team of experienced and highly qualified engineers are always ready to assist customers during the product warranty period according to the manufacturer's regulations, ensuring the factory always operates stably. .

Please contact ESTEC immediately to get detailed advice and quote on the best solution for the customer's factory operating system.