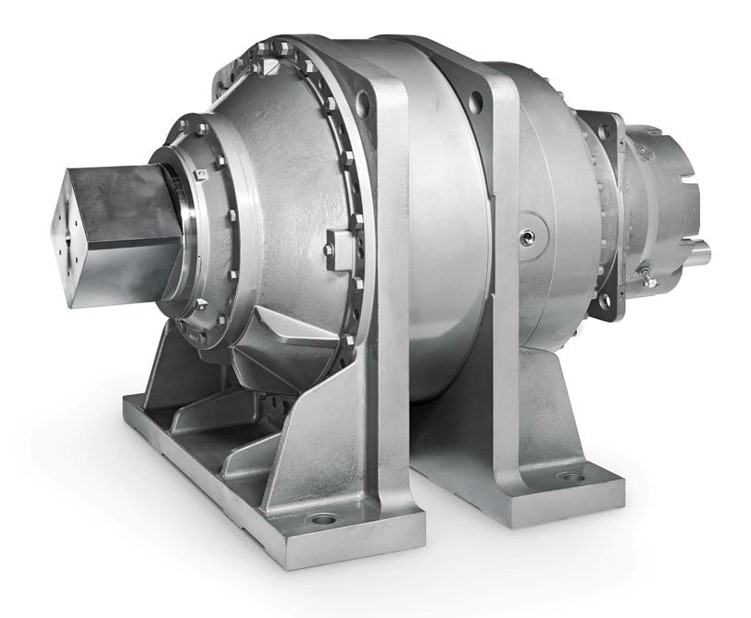

FLENDER PLANUREX2 SUGAR INDIVIDUAL MILL DRIVE

FLENDER PLANUREX2 SUGAR INDIVIDUAL MILL DRIVE

• PLANUREX2 in the form of Individual Mill Drives to drive your mill rolls individually. Highly compact and extremely dependable.

• Automation, Load Distribution, and coordination between the multiple drive modules are done by SIEMENS’ SINAMICS VVVF and SIMATIC Automation Systems.

FLENDER PLANUREX2 SUGAR INDIVIDUAL MILL DRIVE

1.FLENDER PLANUREX2 Sugar Individual Mill Drive

|

Design |

Planetary gear units |

|

Sizes |

30 |

| Gear stages |

2- and 3-stage and gear unit combinations |

|

Power ratings |

up to 14,500 kW |

|

Transmission ratios |

up to i = 4,000 |

| Nominal torques | up to 4,700,000 Nm |

2. General Individual Mill Drive Concept

- Each Roll in the mill tandem is driven individually

3. Strong Points in Choosing Individual Mill Drives

- Increased overall power efficiency

- Redundancy in the system in case one drive module fails

- The right amount of torque at right roll all the time

- Reduce:

- Floor space, less overhead crane width required

- No Tail Bar intermediate shafts, bearing supports, and coupling connections

- No axial forces on the tail bar acting on the gear unit output shaft

- The amount of spare parts, provided the drives are identical

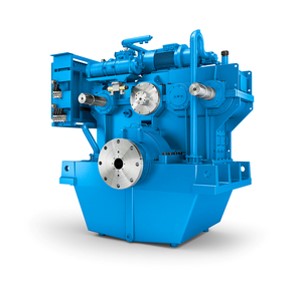

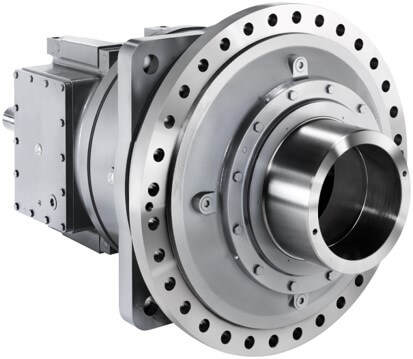

4. Gear Unit Connection to the Mill

- Hollow Shaft Shrink Disc with Torque Reaction Arm

-

Cylindrical Output Shaft, Rigid Flange Coupling, with Torque Reaction Arm

-

Still maintaining “Shaft Mounted” principles but with the added extra ease to release the drive from the Mill.

-

-

We recommend to use Bevel Planetary setup to reduce overhung load on the output shaft induced by the weight of the electro motor.