GEARBOX DIAGNOSTIC

GEARBOX DIAGNOSTIC

- A stable plant requires machinery and good equipment.

- To ensure that we need a plan of maintenance with a reasonable method

GEARBOX DIAGNOSTIC

- Sources of vibration can be:

- Unbalance, eccentricity

- Alignment faults

- Play, backlash

- Gear meshing, gear defects

- Antifriction bearing defects

- Driving machine induced (electrical, belt drive…)

- Process induced (blade passing, resonance…)

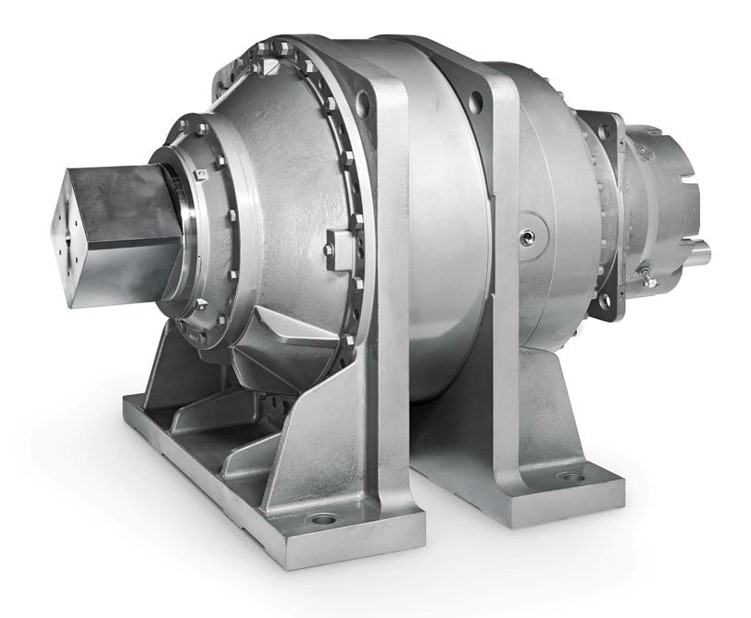

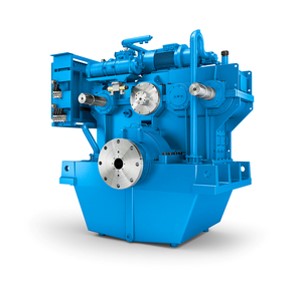

2. Mobile Service

- A flexible and cost-effective solution for both Standard and Application Gear Units

- Measurements using hand-held devices on site by Flender service professionals at regular intervals or when required

- Data evaluation and diagnosis by our competent expert team

3. Benifits of Mobile Service

- Plannable maintenance activities.

- Optimized spare parts management.

- Reduced maintenance costs through early detectionof wear-related anomalies.

- Avoiding failures caused by mechanical overloads