FLENDER HYDRAULIC COUPLING

FLENDER HYDRAULIC COUPLING

Difference conventional mechanical coupling, the transmission of force from the drive shaft (motor, gearbox) to the driven machine shaft (conveyor, water pump, fan, ...) will be based on the mechanical connection mechanism. . A hydraulic coupling is a type of coupling that uses a liquid such as oil or water to transmit the drive force.

FLENDER HYDRAULIC COUPLING

Difference conventional mechanical coupling, the transmission of force from the drive shaft (motor, gearbox) to the driven machine shaft (conveyor, water pump, fan, ...) will be based on the mechanical connection mechanism. . A hydraulic coupling is a type of coupling that uses a liquid such as oil or water to transmit the drive force.

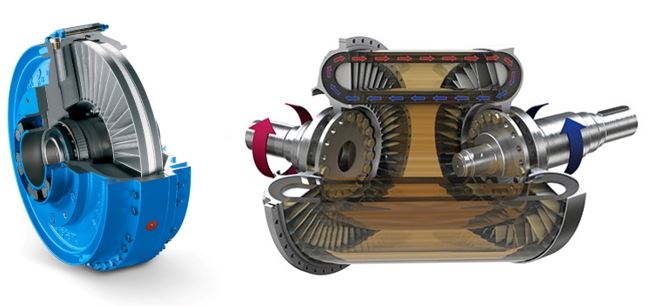

Principle of Operation: When the drive motor rotates, the coupling pump wheel rotates at the speed of the motor and pushes the oil towards the turbine blades (the side of the engine is guided), causing the turbine to rotate and pull the machine to be driven. Thus there is the conversion of mechanical energy into hydraulic energy and vice versa.

The hydraulic coupling works without mechanical contact between the drive shaft and the driven shaft, so when used, it has different advantages compared to hard joints such as:

- The system works smoothly, with little maintenance

- Smooth acceleration of heavy loads without increasing engine power

- Protect and prevent overload and overheating

- High performance

In particular, in cases of problems such as stuck or overloaded drive systems, the hydraulic coupling is capable of troubleshooting and high safety.

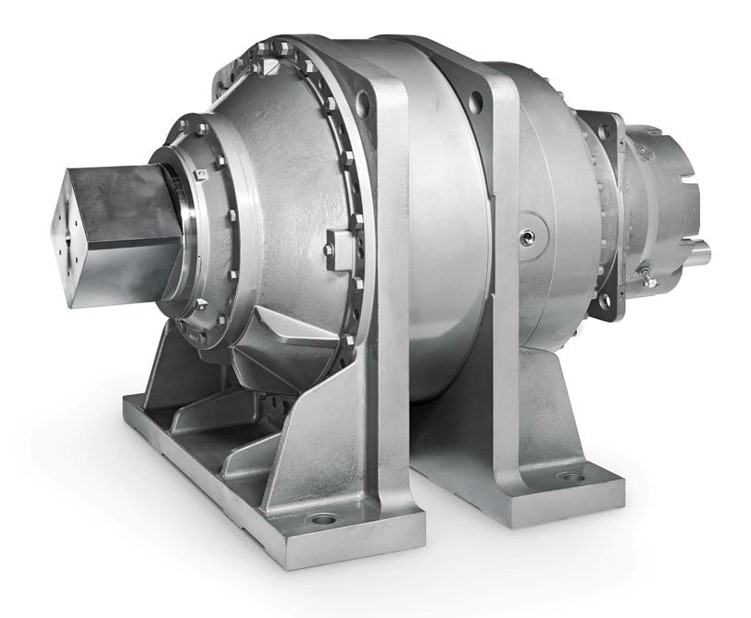

Flender Fludex hydraulic couplings include 4 series:

- Type FA: 7 sizes.

- Type FG, FV, FN: 8 sizes.

Capacity range up to 1,600 KW.

Coupling speed up to 3350rpm.

Fludex hydraulic coupling diameters range from 263mm to 584mm.

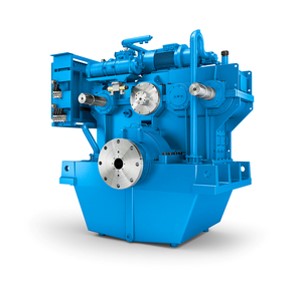

With outstanding advantages, Flender hydraulic couplings are used in almost every industry, from basic standard applications to specialized applications such as ventilation fans, conveyors, buckets, chains. load, mixer, crusher ...

ESTEC provides genuine products with high quality and reliability. Besides, we also focus on after-sales service for customers.

Our team of experienced and highly qualified engineers are always ready to assist customers during the product warranty period according to the manufacturer's regulations, ensuring the factory always operates stably. .

Please contact ESTEC immediately to receive detailed advice and detailed quotation on the best product for the customer's factory operating system.