In the age of the current international integration, automation technology will directly and deeply impact on all manufacturing.

Nowadays, The Fourth Industrial Revolution is creating the dramatic reform in manufacturing technologies. With the advent of digital technologies series, “Automation Production” is converting to “Intelligent Production”.

Technology is always updating over the time. Have your team of automation engineers had a thorough understanding of knowledge to operate factory automation system effectively?

To Invest in specialist knowledge and practical skills: This will be the shortage way for you to catch up the rapid and continuous change of technology. It is a short-term strategy but effective in long-term.

ETSEC is a Solution – Product – Service Provider for Automation and Digitalization in many industries.

We focus on developing human resources, always transferring new technologies and willing to share knowledge.

Come and join with ESTEC’s training courses about “Automation Control Software”.

- PLC & SCADA Training Course (Basic Automation)

Provide trainees with the most general knowledge about programming software for PLC and SCADA control systems. This course is suitable for small to medium production operations. Training Program including 5 courses:

1. Simatic Step 7 Basic Training Course

This courses provide general knowledge about PLC product lines of Siemens; overview of structure of language in programming and the basic function blocks (Data Blocks, Functions and Function Blocks, Organization Blocks, Program Blocks). From there, trainees can program, connect and operate with real PLC.

2. WinCC Training Course

Trainees will train about screen design and programming for SCADA system. From there, trainees can design by themselves, arrange operating screen pages according to industry standard, know how to use basic features in WinCC (control, monitor, warn, store) to apply to the actual production operation.

3. Simatic Step 7 and WinCC Basic Training Course

After this course, trainees can build the control program themselves and understand the control program structure, know how to build function functions, write programs in the Ladder programming language. From there, it is possible to program the control system as well as research and provide solutions to solve problems arising in the actual production of automation control software applications.

ESTEC collaborated with Siemens to conduct TIA Portal training for GreenFeed factory's engineers

4. TIA Portal Basic Training Course

TIA Portal is software that integrates all tasks in automation. From configuration, programming to operating screen design, data management, project storage, trouble shooting and direct access features are all included in the TIA Portal.

To be able to apply knowledge into control operations in actual production at factory,

After course, trainees will be trained overview of the program structure based on TIA Portal. From there, trainees can build a complete program to control and operate for actual production system at factory.

5. Trouble shooting Training Course

After this course, trainees have ability to trouble shooting in HW configuration, trouble shooting for Profibus Network, trouble shooting in Data blocks/Function blocks and monitoring system diagnostic online.

From there, know how to overcome, control and prevent errors to help the system operate stably, shorten maintenance and repair time, bring economic efficiency for businesses.

- Drives Technology Training Course

After finishing this course, trainees will master the principle of operation of variable-frequency drive to apply to the control of motor speed, the working speed of the device attached to the motor.

With a set of practical equipment for SINAMICS G120 & S120 applications, trainees will be trained about the principle of operation of inverter, practice setting parameters of inverter, control inverter in different modes and control inverter via PLC easily, rapidly and professionally.

- Simatic PCS7 Basic Training Course (Process Automation PCS7)

Simatic PCS7 Basic Training Course for Messer Industrial Gas Factory's engineers

PCS7 is a unified system that is supported to provide system solutions, as well as those needed for automation processes.

PCS7 has an open feature, flexible structure, with the ability to change and configure easily, easily expand the system, have high performance and quality, and be applied in almost all manufacturing industries. Export with full of large and small scale.

PCS7 has a full range of control levels: management level, supervisory control level, process control level, scene level.

PCS7 is a modern process control system, built on almost all Siemens hardware and software products, bringing transparency, unity, synchronization, safety and convenience throughout the whole system.

After training course, trainees will understand the program structure in Distributed control system (DCS), building function blocks (APL blocks of PCS7), write control programs and control programming of production systems at factory. In case of needing to handle complicated problems, unexpected incidents in automation control, trainees can completely solve them.

Training Center at ESTEC Digital Factory

Five reasons to choose ESTEC:

- Lecturers with practical experience

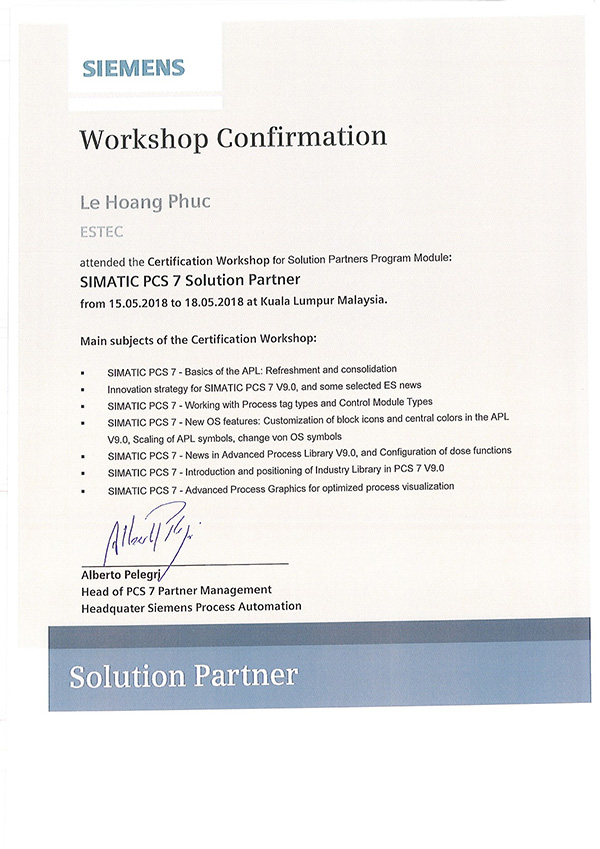

+ ESTEC training’s team: Automation engineers and specialists with many years of experience, implementing the practical projects as well as attend the training courses and get certificate from Siemens.

+ Specialist from Siemens: According to the customers’ specific requirements, ESTEC will invite specialist of Siemens to train.

- Professional training form

+ Documents of training course are standardized from Siemens documents.

+ Practice on models and specialized equipment designed by ESTEC.

- Results – Top priority

+ The trainees had to pass both theory and practice tests before finishing courses.

+ ESTEC will issue a certificate confirming that trainees attend to training courses.

+ ESTEC will provide all documents related to the training courses.

- Diversified participants

+ Engineers of Automation and Electrical at factory.

+ Manager of factory and industrial machinery.

+ Engineer of Automation system design.

+ Factory engineers and technicians need to improve knowledge.

+ Qualified workers need to improve automation skills with PLC.

- Flexible training location

Depending on the needs of trainees and knowledge of each course, ESTEC flexibly arranges training location, with 3 positions:

+ Training Center at ESTEC Digital Factory: Lot A14, Street 7, Da Nang High-tech Park, Hoa Lien, Hoa Vang, Da Nang City.

+ Head Office: 468/13 Phan Van Tri Street, Ward 7, Go Vap District, Ho Chi Minh City, Viet Nam.

+ Training at customer’s factory.

Register now, so we can help you increase professionalism and update new knowledge to apply effectively to work.

Please contact us immediately for detailed consultation about the most suitable training courses, training location and cost quotes.