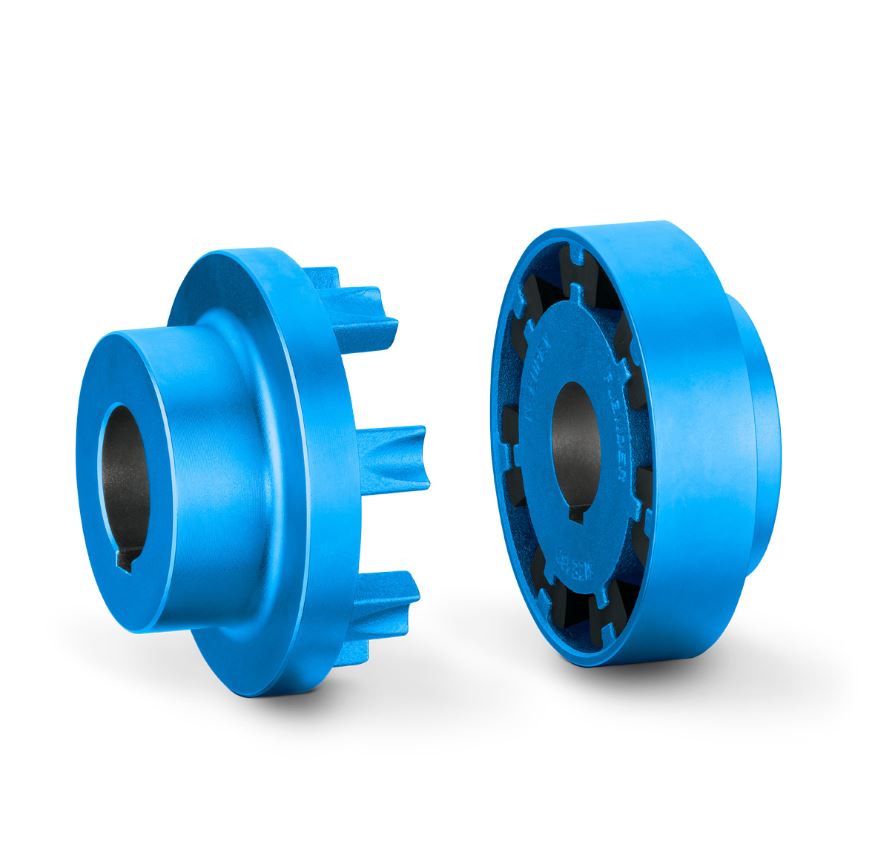

FLEXIBLE COUPLING FLENDER N-EUPEX B

FLEXIBLE COUPLING FLENDER N-EUPEX B

N-EUPEX coupling B series: has a structure of 2 halves of joints that fit together, with rubber damping in the middle. Can bore holes according to the required size

FLEXIBLE COUPLING FLENDER N-EUPEX B

Features: Flender N-Eupex shaft coupling is widely used in various fields of application. N-Eupex couplings stand out for their high reliability and flexibility. Helps increase performance and power for all N-Eupex types: Higher torque, higher rotational speed and resizable.

- Coupling with damping rubber is used to compensate for shaft misalignment

- FLENDER N-EUPEX B couplings have series: N-EUPEX B80, N-EUPEX B95, N-EUPEX B110, N-EUPEX B125, N-EUPEX B160, N-EUPEX B200, N-EUPEX B250

- Temperature from –50 °C to +100 °C

- N-EUPEX couplings are made of high quality cast iron, the shock absorbers are made of neoprene (NBR).

-

Temperature range from –50 °C to +100 °C

N-EUPEX coupling is made of high quality cast iron, the shock absorbers are made of neoprene (NBR).

- Torque range: from 19 Nm - 3,900 Nm

- The range of structural dimensions of the Flender N-Eupex coupling is: 58 - 68 - 80 - 95 - 110 - 125 - 140 - 160 - 180 - 200 - 225 - 250 - 280 - 315 - 350 - 400 - 440 - 480 - 520 - 560 - 610 - 660 - 710.

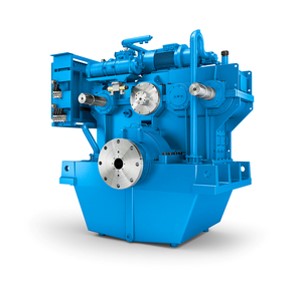

Established as an industrial standard, worldwide in use

- Mining and Cement: heating technology

- Oil and Gas: pumps, fans, compressors, air condensers

- Power Generation: pumps, fans, compressors, air condensers, water turbines

- Chemicals and Pharmaceuticals: driers, lauter tuns, pumps, fans, compressors, mixers, agitators, reactors

- Plastic and Rubber: single- and double-screw extruders

- Pulp and Paper: wastewater purification plants

- Water and Wastewater: aerators

- Food and Beverage: lauter tuns, reactors, agitators, mixers