HOME CARE LIQUID PHASE 3 - UNILEVER

HOME CARE LIQUID PHASE 3 - UNILEVER

Automation - Electrical SolutionsInvestor: Unilever

Location: Cu Chi, Ho Chi Minh City

Year: 2014-2015

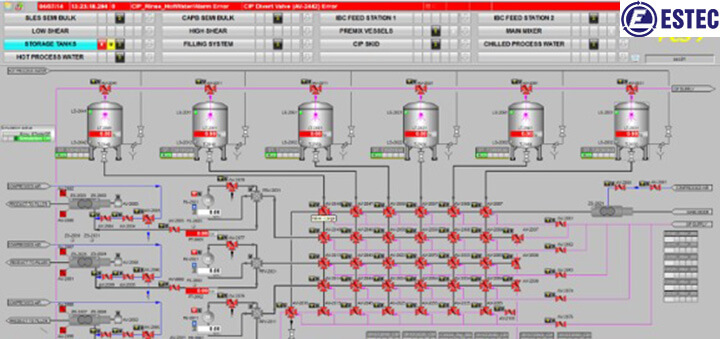

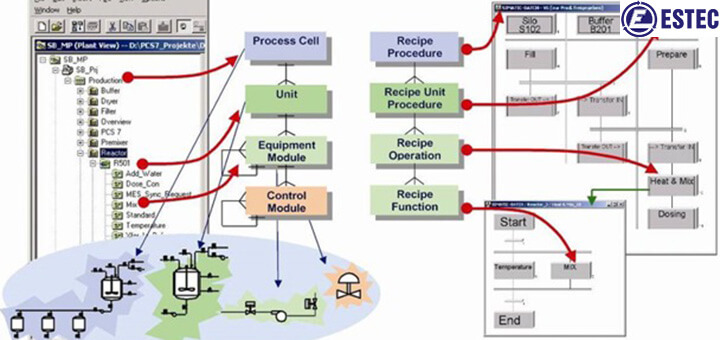

Scope: Upgrade DCS and Batching System at Personal Care Plant

Investor: Unilever

Location: Cu Chi, Ho Chi Minh City

Year: 2014-2015

Scope: Upgrade DCS and Batching System at Personal Care Plant

INTRODUCTION

- Home Care Liquid Plant (HCL) is located in Unilever Cu Chisite. This is the biggest HCL plant of Unilever in term ofcapacity in SEA.

- The plant was built with PCS7 V7.2 andSimatic Batch for the first two phases from 2008-2012.

- ESTEC suppliedthe DCS system for the third phase.

- ESTEC provided HW, SW, engineering PCS7 and Batch,panel assembly, cabling, testing and commissioning.

- Hundreds of new phases were implemented and successfulcommissioned.

CUSTOMER BENIFITS

- Very less shutdown time for the most busy plant of UnileverVietnam

- The project were delivered on time and followed productionschedule.

- The third phase was implemented with less investment costbecause of maximizing the using of existing resources.

- All the production recipes were backed up and reloaded, nolost of production data.

-The plant is optimized to increase capacity and flexibility.