ESTEC implements 5S Standards at the work area. 5S is origin from Japanese seiri, seiton, seiso, seiketsu, and shitsuke, which mean respectively Sort, Set in order, Shine, Standardize, and Sustain.

For each step, we have specific actions as the following:

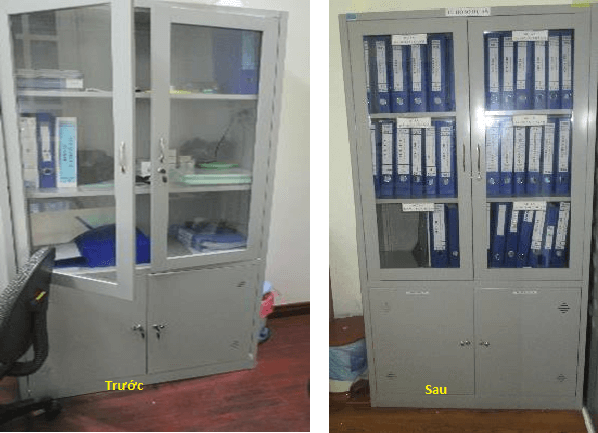

1. Sort: Go through the work area, and elimiate unneccessary things.

2. Set in Order: Arrange things in the right, designated places in the ways that easy to find.

3. Shine: Keep the working environment clean

4. Standadize: Remain a tidy and organanized working area as per standard, so any one works at the station can find the necessary tools.

5. Sustain: The willingness and readiness of teams and individuals to implement 5S activities.

When applying 5S at work area, we will get the benifits from:

1. A tidy, clean, air working place as the uneccessary things have been eliminated.

2. Save time and efforts as things are organised in the ways which are easy to find, and we don't have to look for.

3. Increase the work efficiency and avoid mistakes;

4. Work quality continously increased.

5. Increase the sense of responsibility of employees.

6. Increase the teamwork spirit in the company.